What Are the Different Types of Facial Tissue Machines?

This article breaks down the major categories of facial tissue machines, their functions, production capabilities, and the industries that rely on them. Clear distinctions between systems will help you evaluate ROI, processing specifications, and long-term automation potential. Based on current market trends and equipment performance benchmarks, practical recommendations are provided.

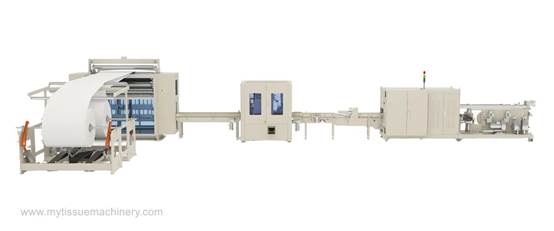

How Facial Tissue Machinery Works?

Facial tissue machinery works by taking a large roll of raw tissue paper and converting it into folded and packaged tissues through a series of automated steps: unwinding, embossing, folding, cutting, and packaging. The machine controls each process with precision to produce uniform, hygienic products efficiently.

Step 1: Unwinding

- A large “parent” roll of tissue paper is placed on the unwinding stand.

- The machine controls the tension to feed the paper into the processing line smoothly.

Step 2: Printing and Embossing (Optional)

- For some products, printing units can apply logos or patterns onto the tissue.

- The embossing unit then uses rollers to press a pattern into the paper, which improves softness, absorbency, and aesthetics.

Step 3: Folding

- The tissue paper is fed through a folding unit, which uses mechanical or air-fold systems to interfold it into sheets.

- This process creates the V-fold or N-fold stacks that are characteristic of facial tissues.

Step 4: Cutting and Stacking

- The continuously folded tissue log is fed into a high-speed log saw.

- A clamping system holds the log steady while a large circular blade, controlled by a Programmable Logic Controller (PLC), cuts the log into individual, uniformly sized packs.

- The machine automatically counts the sheets and stacks them into predetermined quantities.

Step 5: Packaging

- The final stacks of tissues are automatically moved to the packaging unit.

- This unit seals the stacks into soft plastic bags or places them into carton boxes, depending on the desired format.

- Modern machines are fully integrated to ensure a seamless transition from cutting to packaging with minimal human contact.

Major Types of Facial Tissue Machines

Facial tissue machines can be categorized based on their primary function within the production line, such as folding, cutting, and packaging, as well as by their level of automation (semi-automatic vs. fully automatic) and product format (boxed, soft pack, or pocket tissues).

Production Line Machine Types

Facial tissue production typically involves a series of specialized machines working in sequence:

Jumbo Roll Unwinder:

This initial machine feeds large, raw “parent” rolls of tissue paper into the production line while maintaining controlled tension.

Embossing/Laminating Machine (Optional):

These modules can be integrated inline to add texture, decorative patterns, or bond multiple plies (layers) of tissue together, enhancing softness, strength, and visual appeal.

Folding Machine:

A core component that takes the wide paper sheets and folds them into the desired final size and shape. Common fold types include V-fold, N-fold, and interfold (which ensures one-at-a-time dispensing).

Log Saw (Cutting Machine):

After folding, the continuous “log” of tissue is cut into uniform, consumer-sized stacks or logs using high-speed rotary or band saws.

Packaging Machine:

These machines wrap or box the finished tissue stacks.

- Box Packing Machine (Cartoner): Inserts the folded tissues into pre-formed cardboard boxes, automating the filling and gluing process.

- Soft Pack Wrapper: Wraps the tissue stacks in flexible plastic film or polybags, often used for economy or travel-sized “pocket” tissues.

- Bundle Wrapper: A final packaging stage machine that groups multiple individual packs (e.g., 6 or 10 boxes) into a larger, heat-sealed bundle for bulk distribution and shipping.

Automation Levels

Machines are also classified by their degree of automation:

- Fully Automatic Machines: These systems integrate all processes from unwinding to final packaging, minimizing manual labor and ensuring high throughput and consistent quality, ideal for large-scale operations.

- Semi-Automatic Machines: These require some manual intervention for tasks like transferring tissue stacks between stages or for packaging. They are often a more cost-effective and flexible option for smaller-scale manufacturers or startups.

Why Manufacturers Prefer Established Brands

Selecting a trusted manufacturer significantly impacts downtime, spare parts availability, training quality, and post-sales support. With more than 20 engineers and 30+ equipment patents, Mingyang Machinery continues to support factories in over 30 countries, including Southeast Asia, the Middle East, Europe, and the United States.

Manufacturers favor such providers because they offer:

- Tailored machine configurations

- On-site installation and operator training

- Long-term maintenance programs

- Fast global support response

A strong supplier relationship is often as important as the equipment itself in ensuring production continuity.

read more : https://prixdesmenus.com/

Conclusion

Facial tissue machines come in multiple types—interfold, N-fold, box-pack, soft pack, and fully automatic lines—each built for different product formats and production goals. By understanding how these machines function and where they deliver the most value, manufacturers can align their investment with market demand, operational capacity, and long-term scalability.